PTO DRIVE SHAFTS

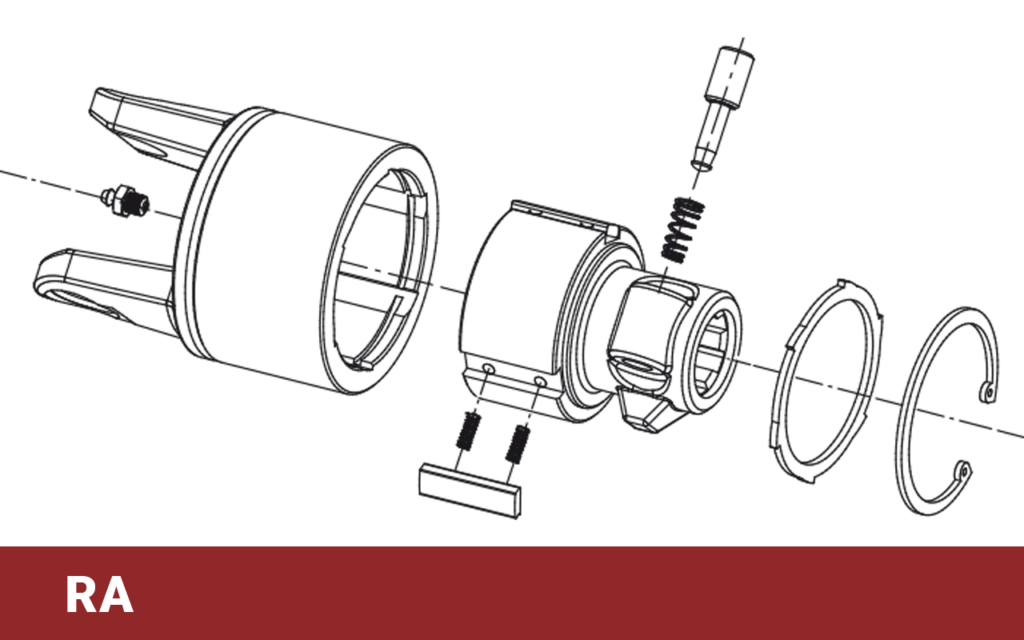

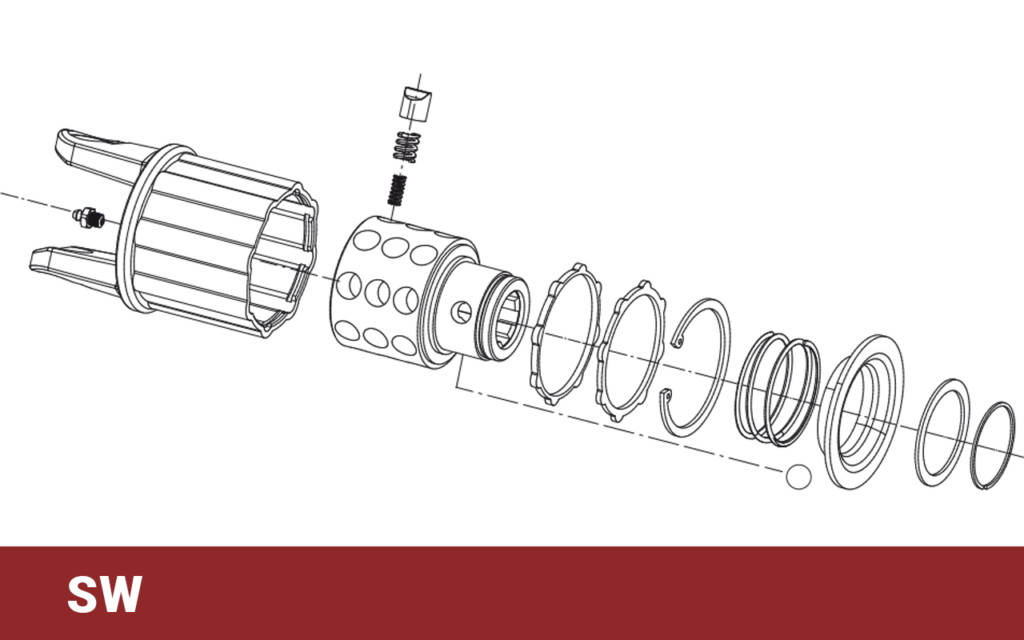

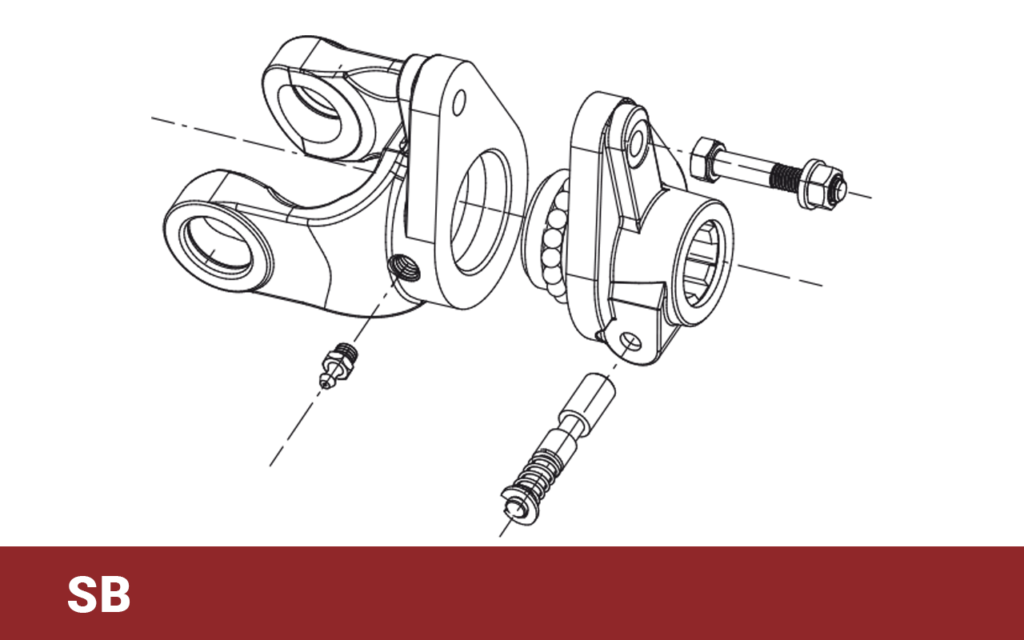

The PTO drive shaft is the mechanical component that transmits power from the tractor (Power Take Off) to the agricultural implements used (Power Input Connection). Each PTO drive shaft consists of two couplings connected together by telescopic tubes. Universal joints consist of two yokes (inner and outer) and a transmission cross joint.

There are two different types of yokes:

Inner for connecting to telescopic tubes. These yokes differ, depending on the type of tube.

Outer to connect to the tractor PTO or the input shaft of the agricultural machine. They differ, depending on the size of the PTO.

The PTO drive shafts produced by CMR Group for the 540-rpm engine speed range from:

CMR Group PTO drive shafts can be used for speeds up to 1,000 rpm. The maximum length of the drive shaft depends on the size of the tubes.

You are advised to consult the technical department for lengths exceeding 1,600 mm.

CMR Group includes in its line of PTO drive shafts a wide range of 80 ° homokinetic cardan shafts. The versions can be with a single homokinetic joint (single homokinetic) or with two homokinetic joints (double homokinetic). The simple version finds application in all conditions in which the operating machine must work even when steering. The double version is mainly used in machines with steering drawbars. Often also used in ditch cleaners. CMR Group homokinetics are made in different sizes, capable of transmitting powers from 35HP up to 130HP based on the number of revolutions which preferably must not exceed 1,000 rpm.

The sizes of the cross joints for PTO drive shafts vary in diameter from 22 mm. to 48 mm. (special versions not mentioned in the general catalogue are available on request) and enable up to 250HP power transmission. The CMR Group range of PTO drive shafts also comprises joints and double joints. Versions featuring connection yokes for tractor PTOs of the types with recessed push-button and/or ball collar and/or ball collar for constant velocity joints are also available in the following spline sizes:

Besides the sizes and types mentioned above, with recessed push-button and/or ball collar, the versions with machine-side yokes are made with:

For technical/quality reasons, the CMR Group range does not include low price PTO drive shafts with welded yokes and tube. The tube with yoke is solely fixed by a spring pin in all PTO drive shafts. CMR Group only uses cross joints with rollers since the sintered versions do not allow the universal joint to operate at an angle without being subjected to early wear. All the transmission components supplied by CMR Group are designed and made in compliance with the mandatory Safety regulations and according to the highest standards of reliability and functionality. For further details, please download the General Technical Catalogue.

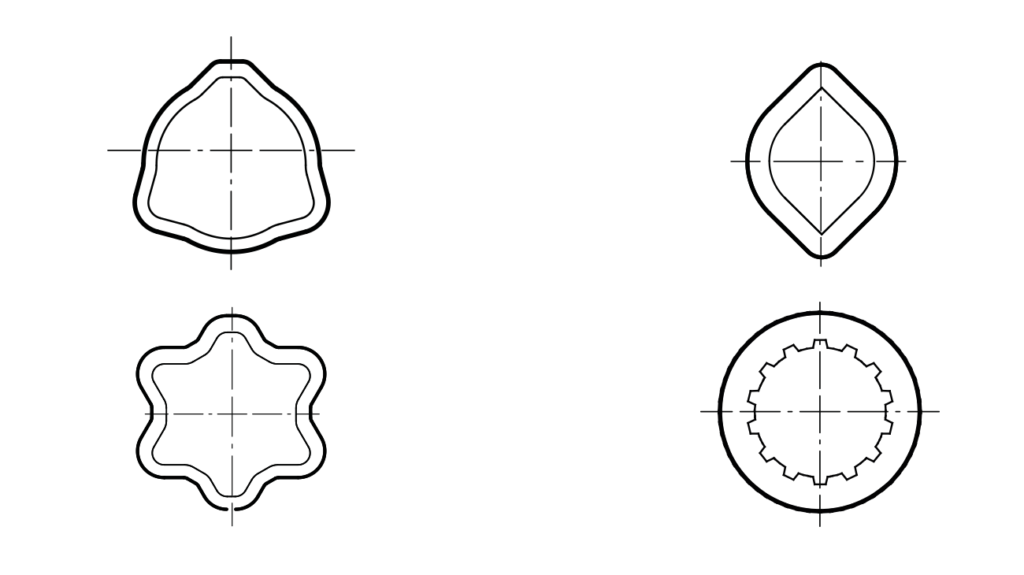

CMR Group offers 4 different series of cardan joints which are distinguished according to the type of telescopic tube envisaged:

Safety devices spare parts

PTO drive shafts must be subjected to thorough routine maintenance at least once a week. Greasing the rotating parts will ensure that the performance specifications indicated in the catalogue are maintained for at least 1,000 hours at working angles up to 5°.

In applications where the machine is liable to move around to a considerable extent, the following parts of the PTO drive shaft are the ones most subject to wear:

– the telescopic tubes and safety guards, since the tubes are continuously being withdrawn

– the cross-joints, since the angles are frequently changed

– the limiters, owing to frequent use.

CMR Group recommends annual maintenance, to coincide with the beginning of the new agricultural season, at which time the above mentioned components should be checked to make sure they function correctly.

If faults are discovered, the worn parts must be replaced to prevent the entire transmission from being damaged.

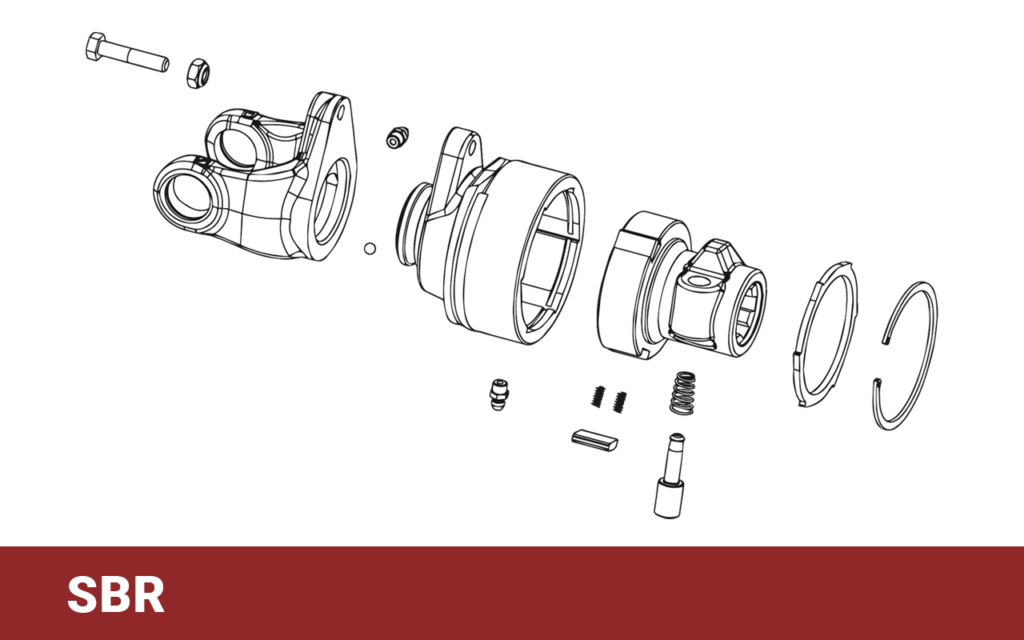

CMR Group provides parts lists based on the drawings supplied to the Customers and technical catalogues with exploded drawings to ensure that the replacement parts can be identified. The instructions for installing the parts are given in the operation and maintenance manuals supplied with each PTO shaft at the time of sale.

CMR Group has a large inventory of replacement parts which are always in stock. These parts include:

Spare parts

Fill out the contact form or request a consultation from our Technical Department