CMR Group also supplies sand castings up to 200 kg in weight in alloyed steel or stainless steel. Thanks to precision casting smelting technology, there are no limitations as to minimum lot quantities.

Growing demands from the market to reduce the cost of mechanical machining of sand-cast steel parts encouraged CMR Group to develop and expand their use of precision casting (or “lost-wax” casting) technology.

The production facilities for these products are situated in the Far East for various reasons, among which:

Know-how, tried-and-tested production processes, modern machinery and the best leading-edge technologies plus qualified, expert personnel enable CMR Group to speed up and optimize the initial stages of the projects.

Low cost precision casting moulds means that limited production lots can also be supplied, thus with low impact in terms of mould depreciation.

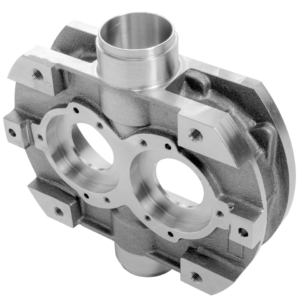

Precision casting technology produces parts very similar to finished products, even when their shapes are extremely complicated.

This technique also does away with problems concerning casting drafts and undercuts, which usually occur when sand casting techniques are used.

Very high-quality surface finishes can be obtained thanks to the use of the most advanced precision casting technologies, including the creation of logos and trademarks with excellent definition.

A vast range of materials can be used for precision casting: alloyed steel, stainless steel, aluminium, bronze and other alloys of various types enable parts for the most varied applications to be produced: from components for agricultural machinery and earth moving machines, to parts for the ship-building, food, mechanical, furniture industries and machinery components.

Based on the Customers’ drawings, CMR Group can supply both “blanks” and already machined parts using conventional machine tools and machining centers (CNC), also with mirror-polished or satin-finish surfaces.

CMR Group‘s industrialization department works together with the Customer to design, develop and produce precision-cast parts to replace those originally made by metal-working methods, often achieving cost reductions and obtaining aesthetically more attractive components.

| Non-alloyed steel | Stainless steel | Other materials |

|---|---|---|

| ASTM A 105 | AISI 303 | 16CrNi4 |

| UNI 7845-78 C20 | AISI 304 | EN 10025 S355JR |

| UNI EN 10083-1:1998 C40 | AISI 316 | EN 10293 GS240 |

| – | AISI 316L | ASTM A352 025LCB |

Fill out the contact form and send us your drawings or request a consultation from our Technical Department