We produce mechanical components in Zamak-Zama alloy for various industries, including the lighting, automotive and hydraulic sectors.

Die-casting is one of the most widespread methods in the world for obtaining mechanical parts in light aluminium, zinc and magnesium alloys. (learn more) …The process is cheaper than sand or shell-mould casting, while still maintaining extremely high precision standards.

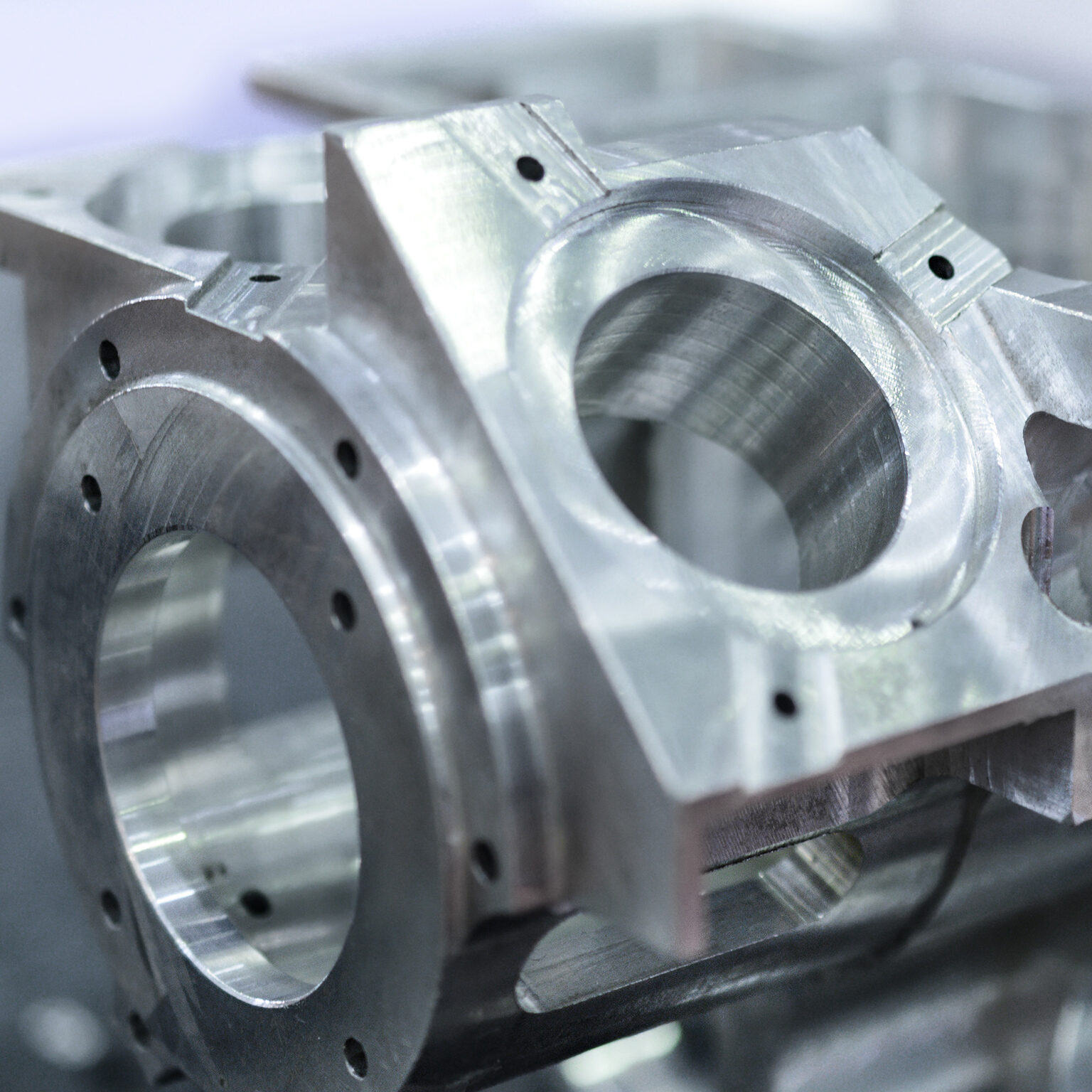

CMR Group produces various different die-cast parts, both for its own production range and on behalf of third parties, including: industrial reduction gears, final drives for agricultural machinery, various mechanical components for industrial installations and parts made to the Customers’ precise specifications.

Thanks to production departments outfitted with presses in different sizes (up to 1,800 tons), 5-axes machining centers and EDM machines, CMR Group‘s production facilities are able to manufacture die-cast parts in various sizes, dies with die holders and workpiece extraction carriages.

The most commonly used materials for die-casting are:

Checks are performed by CMR Group when the raw materials are received, during the processing cycles and on the finished products.

The modern monitoring equipment and instruments are regularly calibrated as required by the mandatory Quality regulations and include:

Equipped with these technologies and highly qualified personnel, CMR Group is also competitive as to the cost of the parts produced and the cost of the investment required in order to create the dies.

CMR Group can supply the first samples within a very short time and is also quick to modify the fixtures if this should be requested by the Customers.

Depending on the Customers’ requirements, the parts can be supplied as “blanks” or after having been subjected to mechanical machining operations, including impregnation. The entire mechanical machining cycle is performed on machine tools and machining centers (CNC).

Fill out the contact form and send us your drawings or request a consultation from our Technical Department